| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

KATAY MAKİNE MÜHENDİSLİK OTOMOTİV SAN. VE TİC. LTD. ŞTİ.

Organize Sanayi Bölgesi 109. Cad. No: 9 / Odunpazarı / ESKİŞEHİR / TÜRKİYE

|

Contact Info: +90 532 665 1038

|

Hall: 5

Stand: 504 C

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Katay is a distinguished engineering company specializing in comprehensive packaging solutions, encompassing a wide array of applications, including Stretch Film Wrapping, Foam, PE, and Bubble Nylon Film. Under the official trademark Dynawrap, we introduce Horizontal Stretch Film Wrapping Machines, which have garnered a global presence, operating successfully in over 40 countries worldwide. Dynawrap s commitment lies in crafting the most robust machines while incorporating the cutting-edge technology available in the market. This dedication is underpinned by the utilization of premium European components, a structurally robust design, and a wealth of industry knowledge, culminating in Dynawrap Wrapping Machines being positioned as the pinnacle of quality in the market. Our primary objective is to deliver superior products to the market, achieved through active listening to our customers feedback and a continuous commitment to refining our services and product offerings. With a wealth of knowledge and technological expertise acquired over 15 years of market presence, Dynawrap is primed to provide state-of-the-art solutions. At Window Eurasia 2023, we are excited to present an extensive range of products, including Horizontal Stretch Film Wrapping Machines, Vertical Stretch Film Wrapping Machines, Expandable Paint Drying Racks, and Robotics. This reaffirms our commitment to staying at the forefront of innovation and addressing the evolving needs of our valued customers.

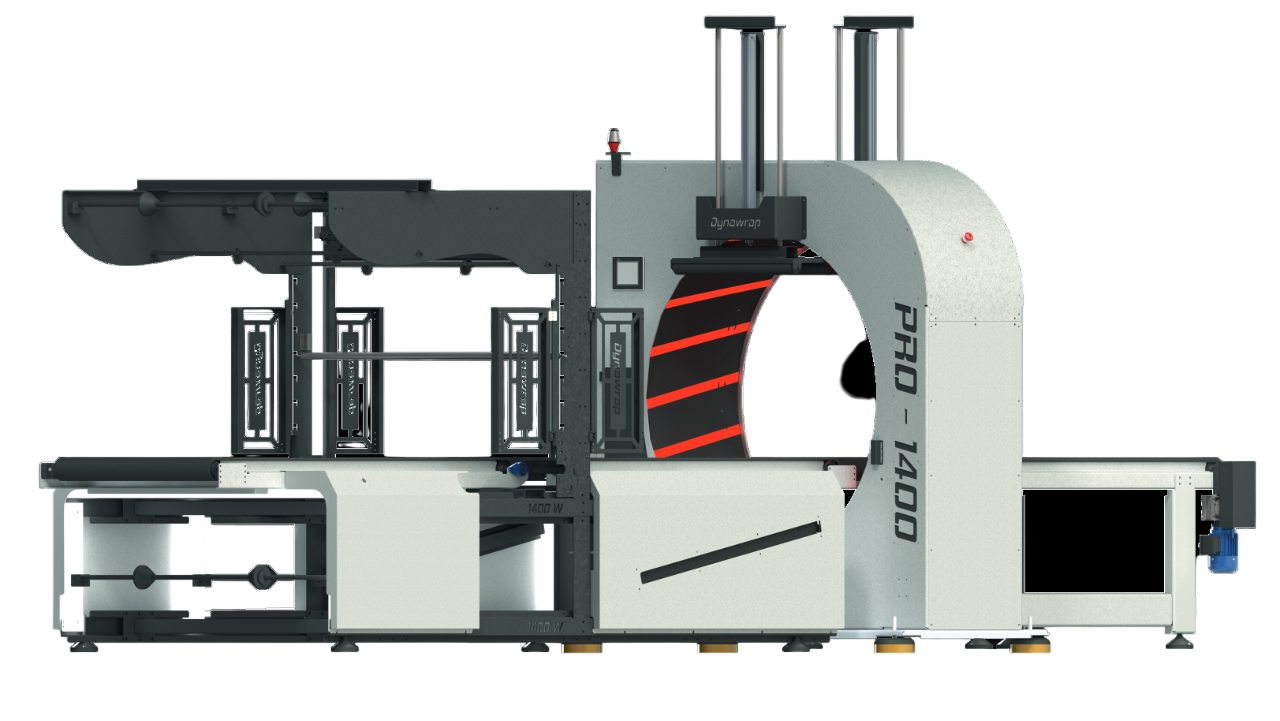

The Pro Series fully automatic horizontal wrapping machine is an enclosed model, featuring integration with an additional air bubble and PE foam application unit. The Dynawrap Pro 1400W Wrapper has been meticulously designed to offer exceptional flexibility while maintaining the high-speed performance demanded in product packaging. Our PRO SERIES Orbital Wrapping machines are distinguished by their utilization of premium European and Japanese components, including well-regarded brands such as Schneider, Beijer, and Omron. The Pro Series boasts a sturdy chassis and structure, exemplifying its durability. As a testament to our commitment to quality, Dynawrap offers an extensive 10-year chassis warranty for all horizontal stretch film wrapping machines. The PRO Series W Stretch Film Horizontal Wrapping Machine is the model that includes an integrated welding unit. With a length of 6 meters (or 6700mm for the 1700W model), this machine provides a remarkably versatile solution for packaging a wide range of products, including furniture, doors, panels, wooden boards, cabinets, windows, and bulky items. The W series allows for the application of air bubble and PE foam to provide robust protection, complemented by a top layer of stretch film. The PRO Series Stretch Film Wrapping Machines under the Dynawrap brand are equipped with Industry 4.0 features, setting a new standard by offering comprehensive reporting capabilities that allow you to measure and enhance your manufacturing processes and productivity. All Dynawrap Pro Series Orbital Stretch Film Wrapping Machines are equipped with standard top presses, automatic cutting mechanisms, clamping units, and conveyors, ensuring a seamless and efficient packaging operation. Maximize the benefits of the Pro s Standard Package, which includes: Pneumatically Controlled Stretch Film Clamping & Cutting Unit Pneumatically Controlled Infeed and Outfeed Top Presses Motorized Infeed and Outfeed Conveyors featuring Italian anti-slip 5mm thick PVC Green Belts 7 Touch Panel Human-Machine Interface (HMI) Screen Should you have any further inquiries or wish to discuss how our Pro Series can optimize your packaging requirements, please feel free to contact us.

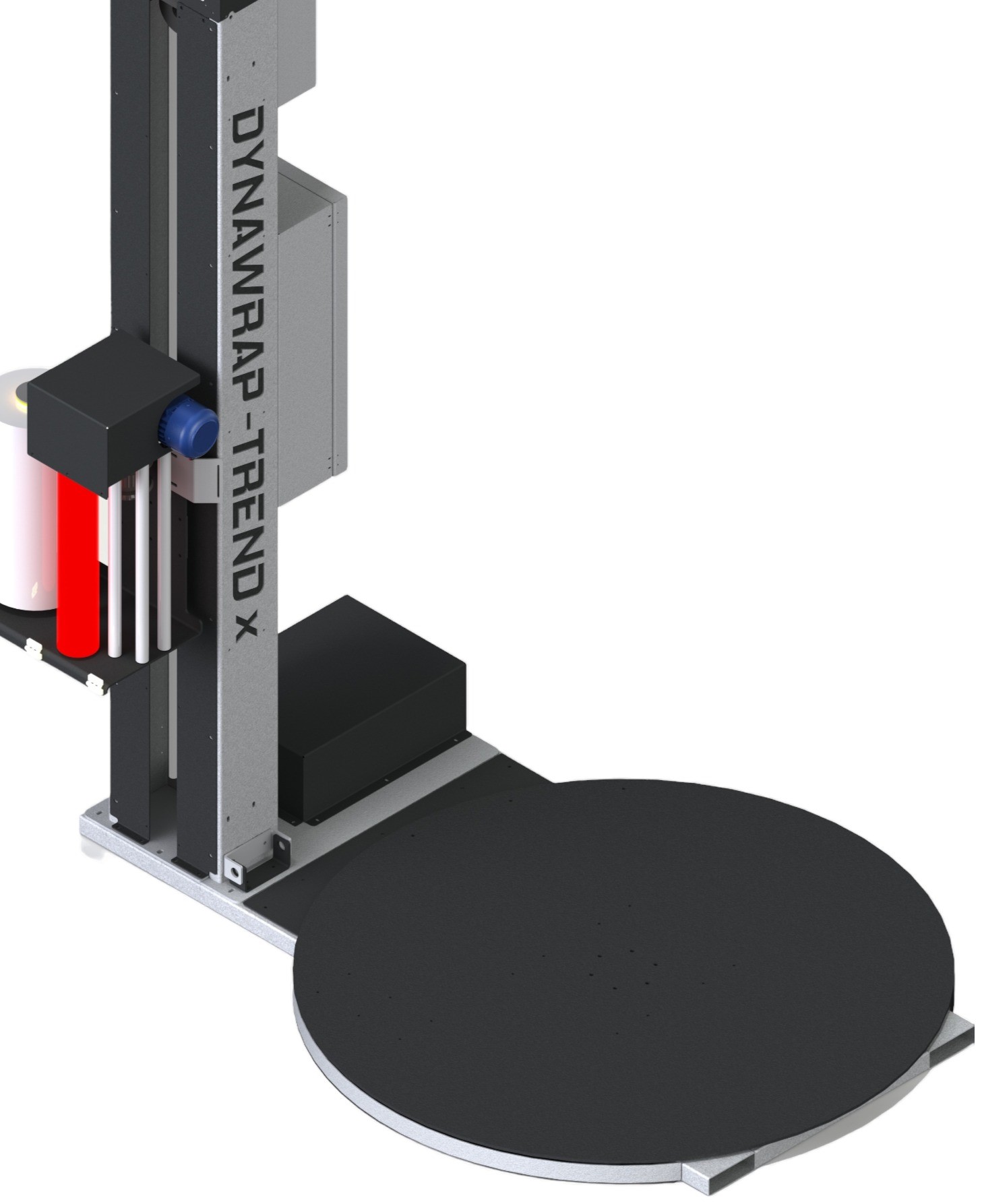

The TREND stretch wrappers, part of our robust turntable model lineup, are celebrated for their exceptional performance and user-friendly design. These machines from the TREND series offer a multitude of options and variants, allowing for a high degree of customization to meet the unique needs of our diverse clientele. With an impressive output capacity of up to 25 pallets per hour, the TREND series stands as a versatile solution that can be tailored to address a wide range of customer requirements. Central to the TREND Series Pallet Wrappers is the inclusion of a cutting-edge 7-inch touch panel. This user-friendly interface is not only highly programmable but also engineered for long-lasting functionality. This feature ensures that our TREND Series machines are not only responsive to evolving packaging needs but also built to endure the rigors of extended use, delivering consistent and reliable performance over time.

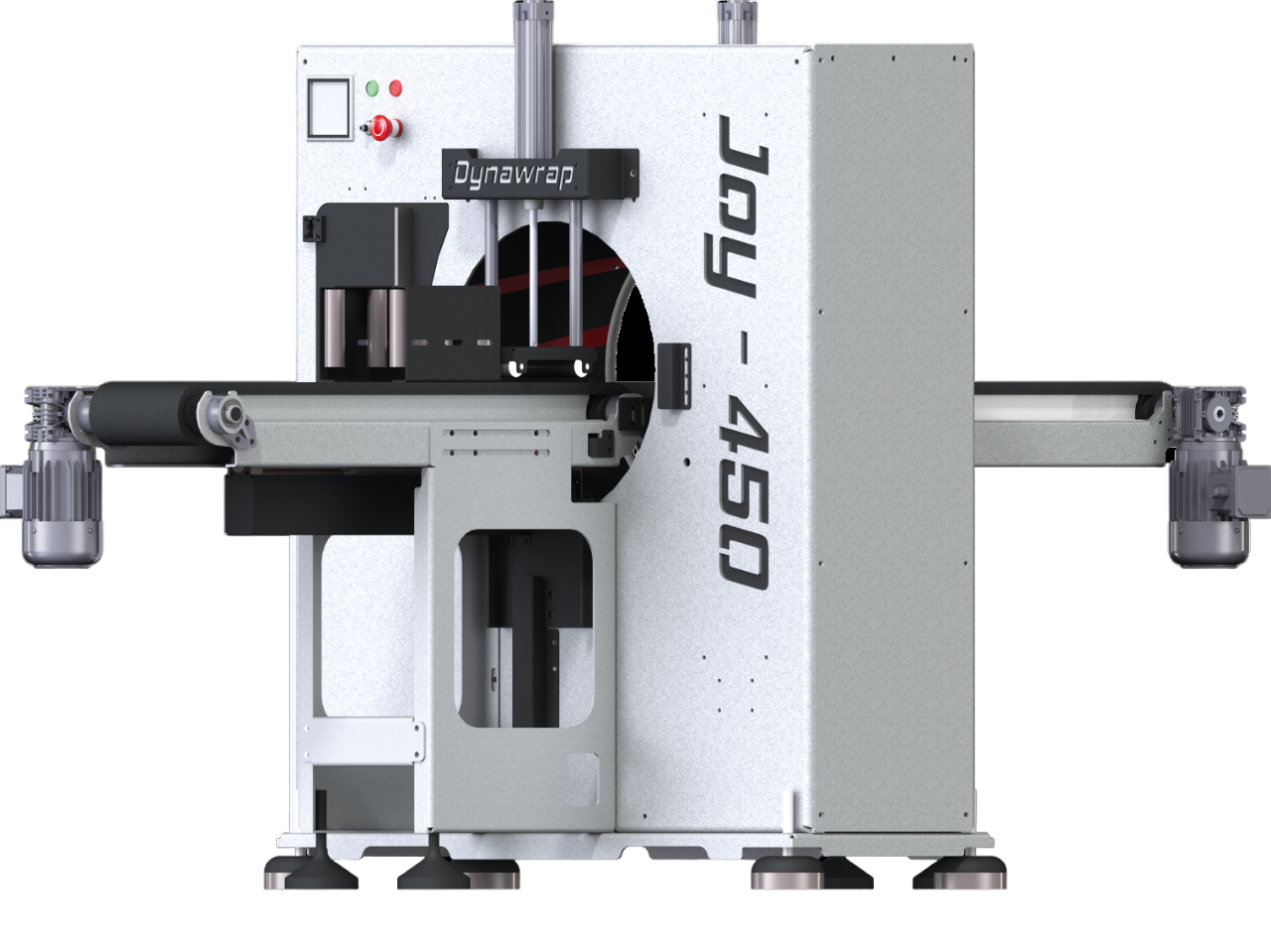

The Joy 450 Orbital Wrapper epitomizes engineering excellence, seamlessly merging unwavering reliability with cutting-edge technology, thereby establishing new benchmarks in both performance and dependability. This impressive machine, characterized by its swift wrapping capabilities, is ideally suited for a spectrum of industries, including woodworking, cabinetry, and PVC packaging, where precision and efficiency are paramount. Crafted with versatility in mind, the Joy 450 exhibits the capacity to adeptly manage a diverse array of products, ranging from moldings and aluminum profiles to PVC constructs, shelves, blinds, and kit furniture. Moreover, this machine can be further tailored to meet your unique packaging requirements through a host of customizable features. Furthermore, underpinned by a legacy of 15 years of industry expertise, the Joy 450 not only offers a cost-effective solution but also optimizes your packaging processes, significantly reducing both packaging time and stretch consumption. The integration of an efficient product type switch, requiring less than 3 seconds, further underscores its prowess in enhancing productivity. Engage in a collaborative partnership that propels your business to new heights with the Joy 450 Horizontal Stretch Film Machine. Beyond its role as a mere piece of equipment, it serves as a conduit for elevating your packaging operations, facilitating increased efficiency and unwavering reliability.

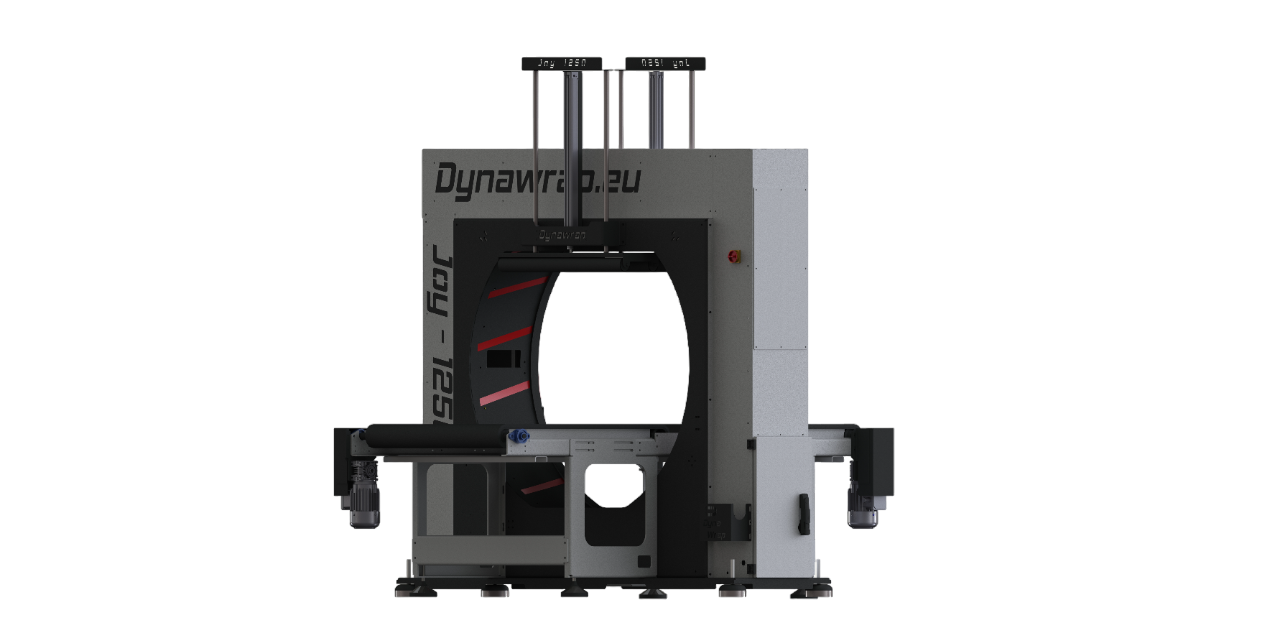

The Joy Series 1250 Horizontal Wrapping Machine epitomizes impeccable manufacturing standards, setting a remarkable precedent for performance and reliability. This machine boasts an efficient wrapping speed, delivering swift and precise packaging, rendering it an ideal choice for diverse applications within the cabinetry and woodworking industry. With a generous 1250 mm width net inner diameter, and powered roller conveyors in the infeed and outfeed, it supports a fully automatic integrated process. The machine s standard length is 2.2 meters, but we offer customization options to cater to the specific needs of our customers. User-friendly programming simplifies the operator s tasks, making the Joy Orbital Stretch Wrapper highly versatile in handling an extensive range of products. From moldings and aluminum profiles to PVC profiles, shelves, blinds, cabinets, doors, and kit furniture, it accommodates a wide array of items. The Joy 1250 also offers a suite of optional features that can be tailored to precise requirements, enhancing functionality and ultimately maximizing business productivity. It s a machine that adapts to your unique needs, offering bespoke solutions for your cabinetry and woodworking packaging processes. In addition to its outstanding qualities, the Joy 1250 Horizontal Wrapping Machine presents a cost-effective entry point for businesses. Its full automation streamlines the packaging process, eliminating the need for manual intervention. With its efficient operation and automated functionality, the Joy 1250 delivers exceptional value to businesses seeking efficient and reliable packaging solutions in the cabinetry and woodworking industry. The competitive edge of the Joy Series extends beyond its remarkable features. With 15 years of industry-specific expertise underpinning its design, it s meticulously crafted to not only meet but surpass customer expectations. Its economical initial investment, coupled with full automation, positions it as an industry leader in cost-effectiveness. This transformative technology dramatically reduces the packaging process from 8-man-hours to just 1 man-hour, simultaneously reducing stretch consumption by more than 50%. This machine, which eliminates the need for manual intervention, optimizes the packaging process, making it an unparalleled choice for businesses in search of an efficient, reliable, and budget-friendly packaging solution. Elevate your packaging capabilities and embrace newfound levels of efficiency and reliability with the JOY 1250 Horizontal Stretch Film Machine. It s not just a machine; it s your key to enhancing your packaging operations and unlocking unparalleled productivity in the cabinetry and woodworking industry.

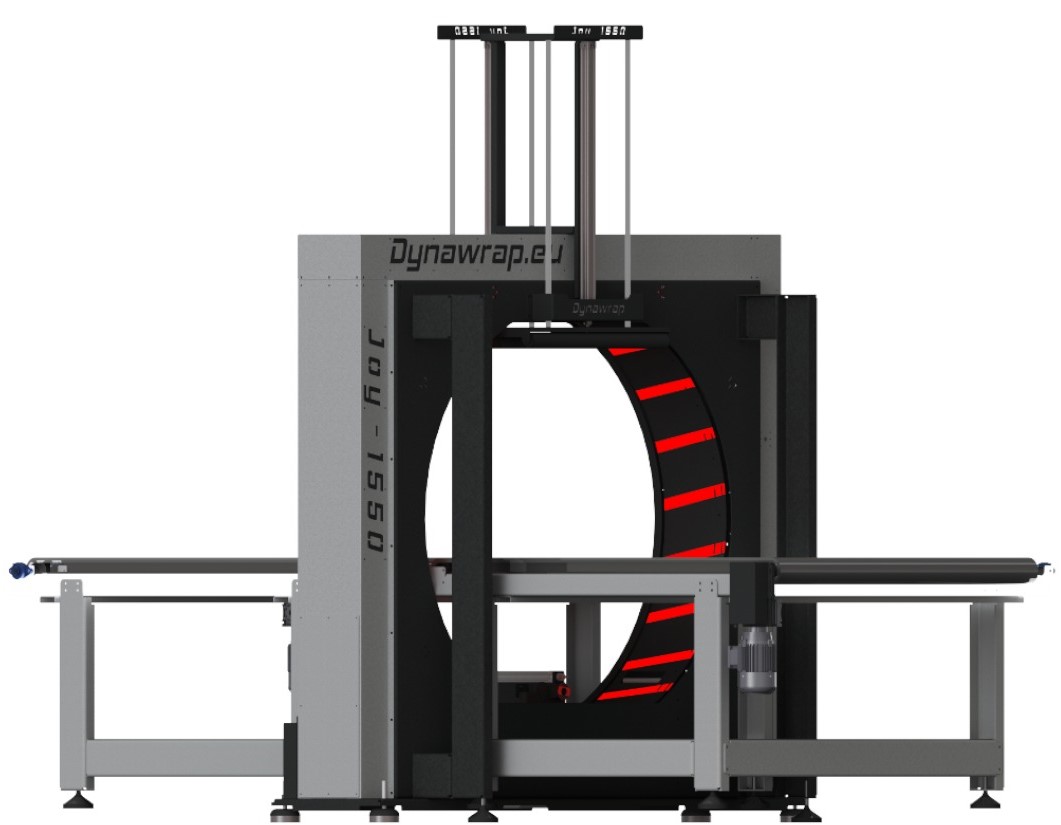

Introducing the Joy Series 1550 Horizontal Wrapping Machine, the newest addition to the Dynawrap Product Range. This compact, reliable, and cost-effective machine is designed for effortless ownership. The Joy Orbital Stretch Wrapper boasts an impressive 1550 mm net inner diameter and features user-friendly programming, simplifying the operator s tasks. At its core, the Joy 1550 Horizontal Wrapper embodies the essence of PRO within the JOY framework. It has been meticulously engineered for those who seek seamlessness in their packaging endeavors, making every process feel fluid, whether you re packing cabinets, doors, or frames. This machine comes equipped with a driven roller conveyor in the infeed and outfeed, supporting an entirely automated overall process. The machine s standard length is 3.75 meters, with customization options available to tailor it precisely to our customers unique requirements. Beyond its remarkable features, the Joy Series s competitive edge extends beyond ordinary expectations. With 15 years of industry-specific expertise woven into its design, it transcends the standard, exceeding not only customer expectations but also our own commitment to surpassing industry norms. The Joy Series is a leader in cost-effectiveness, marked by its economical entry-point investment and fully automated functionality. It dramatically reduces the packaging process from 8 man-hours to just 1 man-hours, simultaneously cutting stretch consumption by more than 50%. This machine eliminates the need for manual intervention, optimizing the entire packaging process. In essence, it stands as the unparalleled choice for businesses seeking an efficient, reliable, and budget-friendly packaging solution.

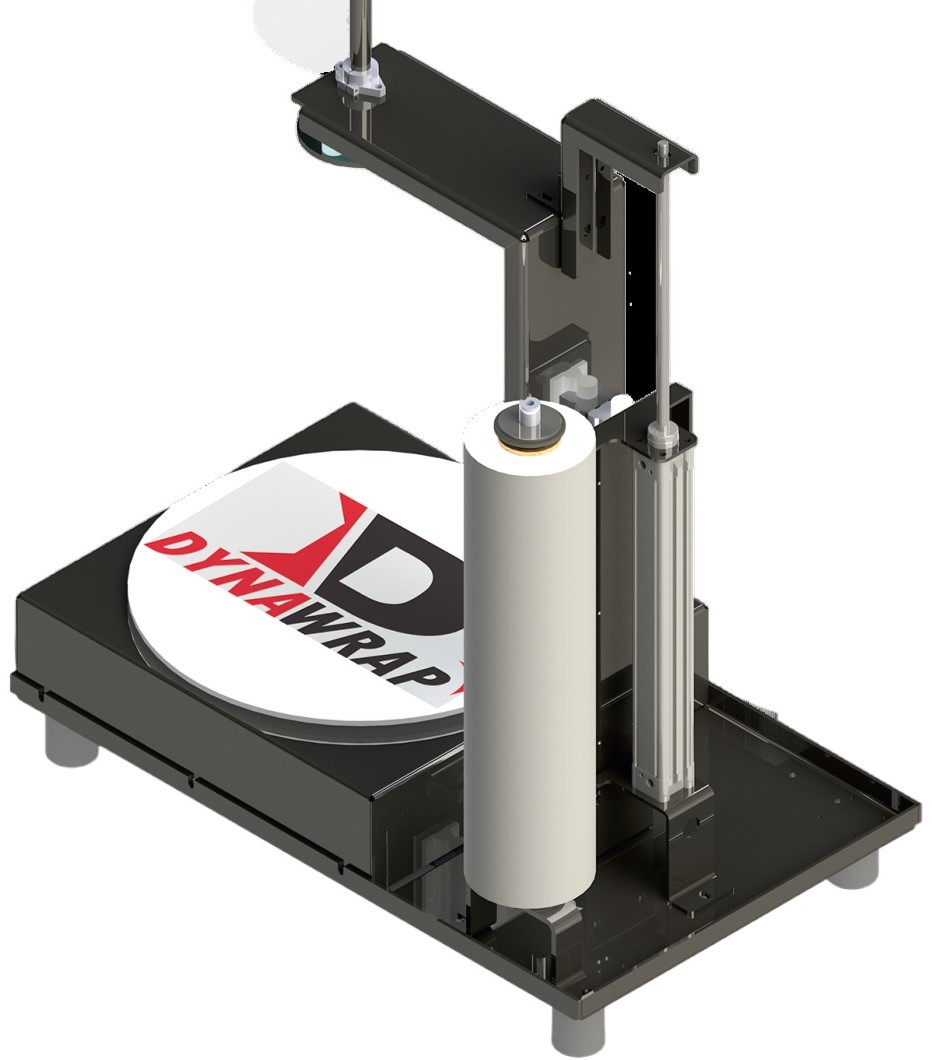

The Dynawrap Petty Vertical Wrapping Machine represents the epitome of efficiency and precision when it comes to packaging items like boxes, chairs, doors, cabinets, and windows using stretch film. This machine s versatility is a standout feature, offering the capacity to manage loads of up to 200 kg. For those larger items, an optional 1.5-meter height and a diameter plate of 1200 cm provide ample space for secure and effective wrapping. The up-and-down moving tower, effortlessly controlled with a joystick, adds an extra layer of convenience and adaptability. This feature allows you to easily adjust the height as needed, ensuring that the machine accommodates a wide range of items, from smaller packages to more substantial cargo. The top pneumatic stabilizers and self-holding system are carefully designed to enhance stability throughout the packaging process, guaranteeing that your items are securely wrapped. As a semi-automatic wrapper, the Dynawrap Petty Vertical Wrapping Machine strikes a perfect balance between compactness and operational efficiency. Not only does it save valuable time by streamlining your packaging processes, but it also contributes to resource conservation by using stretch film judiciously. Its design reflects a commitment to environmental sustainability while maximizing the protection and stability of your products. This machine is more than just a tool; it s an investment in your business s efficiency, productivity, and sustainability. The Dynawrap Petty Vertical Wrapping Machine serves as a testament to our dedication to delivering practical, cost-effective, and environmentally conscious solutions to meet your specific packaging requirements. Experience the synergy of precision and versatility as you enhance your packaging operations with this exceptional piece of technology.

The Dynawrap Easy Vertical Wrapping Machine stands as the ultimate solution for efficiently wrapping packages, particularly those with weights up to 50 kg and a height of 50 cm. This machine is meticulously designed, equipped with a top pneumatic stabilizer system, and serves as an ideal choice for packaging smaller products, such as accessories for cabinets, doors, and kit furniture. At the heart of the Dynawrap Easy Wrapping Machine lies a commitment to optimizing your packaging processes, enhancing overall efficiency, and reducing operational costs. This machine incorporates advanced features and unwavering reliability, making it the perfect solution to address your specific packaging requirements. Let s explore some of the key benefits: High-Speed and Precision Wrapping: The Dynawrap Easy ensures high-speed and precise wrapping, making it well-suited for packaging small to medium-sized packages with exceptional accuracy. Customizable Settings: The machine s settings are fully customizable to align precisely with your production requirements. This flexibility guarantees that it can adapt to a wide range of packaging needs. Sturdy Construction: Built with a robust construction, the Dynawrap Easy Wrapping Machine is engineered to deliver long-lasting durability, ensuring it remains a reliable asset for your operations over time. Ease of Maintenance: The machine is designed with user-friendly maintenance in mind, minimizing downtime and operational disruptions. This enhances your overall efficiency and productivity. Expert Customer Support: Backed by expert customer support and comprehensive warranty coverage, you can have peace of mind knowing that your investment is safeguarded. Investing in the Dynawrap Easy Wrapping Machine represents an acquisition of a top-tier wrapping solution that secures long-term operational excellence for your business. It ensures that your packaging processes are not only efficient but also precise and reliable, contributing to the overall success and competitiveness of your operations.

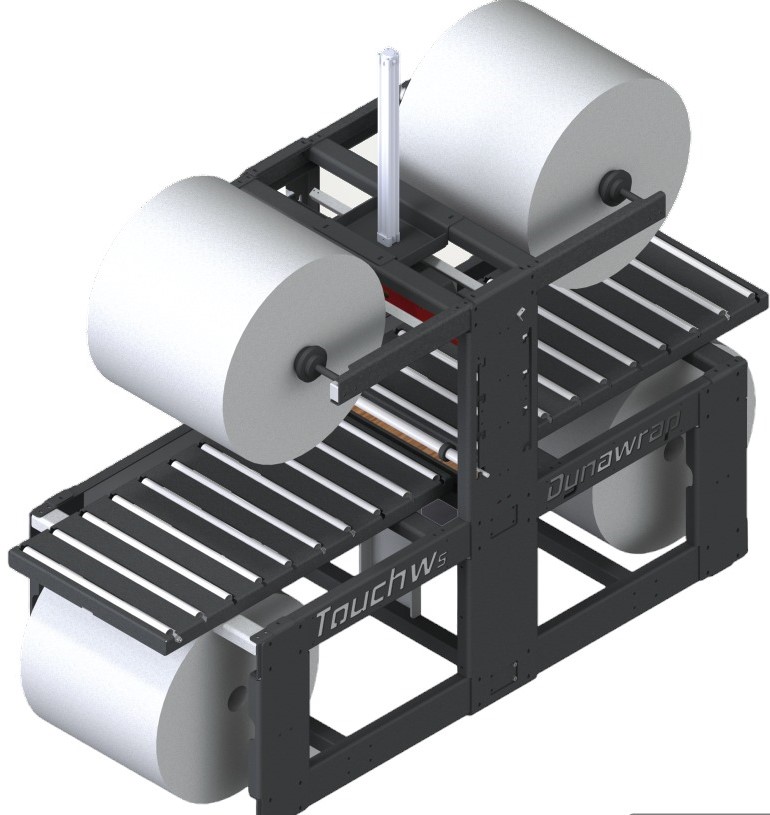

The Dynawrap Touch presents an ideal solution for semi-automatic packaging with an integrated Total Closing Unit, designed to accommodate an array of options and variants. Part of the Touch Series, this machine seamlessly integrates with both the Pro Series and Joy Series, offering remarkable compatibility and flexibility in your packaging operations. One of the standout features of the Dynawrap Touch is its capability to apply foam, PE film, or air bubble material as an initial layer, followed by a stretch wrap on top of it. This innovative process is known as total closing, and it involves sealing all six sides of the product. This method not only enhances protection on the sides but also provides extra safeguarding, particularly for the corners of your items. The integration of a Total Closing Unit within the Dynawrap Touch signifies a commitment to maximizing the safety and protection of your products during transit or storage. This thoughtful and advanced approach ensures that your items are not only securely packaged but also safeguarded against potential damage, particularly at vulnerable edges and corners. The Dynawrap Touch offers a sophisticated solution that caters to the evolving needs of modern packaging, making it an invaluable addition to your operations. Whether it s for protecting delicate or valuable items, or simply ensuring that your products arrive in pristine condition at their destination, the Touch Series represents a pivotal advancement in packaging technology.

The Robo Wrap Model is a remarkable self-propelled stretch-film wrapping robot designed to handle an array of palletized loads with varying shapes, sizes, and weights. This cutting-edge machine is equipped with a user-friendly digital color display measuring 7.2 inches, which provides a simple and highly functional interface for adjusting programs and wrapping parameters with ease. Additionally, it features the convenience of remote control activation for initiating the wrapping cycle. The Robo Wrap Model prioritizes safety and security with the incorporation of a protection system, including a safety bumper. This intelligent safety feature ensures that the machine halts immediately upon encountering an obstacle, minimizing the risk of accidents and damage during the wrapping process. With an impressive capacity, this robot can effectively wrap pallets up to a towering height of 2,800 cm. Its adaptability to a diverse range of loads and its commitment to user-friendly operation make the Robo Wrap Model a valuable addition to any business seeking efficient and secure pallet wrapping solutions.

The Dynawrap Rack Series is distinguished by its intelligent and versatile design, capable of accommodating a wide range of products. It represents a groundbreaking solution in the realm of door painting systems, as it allows simultaneous painting and drying of both sides of various items such as cabinets, regular doors, shutters, windows, shelves, and more. This innovative approach not only optimizes time and space but also contributes to substantial cost reductions. At the core of this range is the Dynawrap Expandable Drying Rack, which is equipped with all the essential features necessary for a workshop s efficient operation. This expandable drying rack is a dependable workhorse, particularly well-suited for cabinet shops. Its robust design and sturdy structure make it ideal for heavy workloads, and its expandable and adjustable nature ensures that it can be tailored to meet specific needs. The Dynawrap Expandable Drying Rack is available in various configurations and dimensions, catering to diverse workshop requirements. Technical Data: Dimensions (Opening): 300 × 1250 mm (320 x 1250) (1750x2300) Shelf Length: 700-900-1000 mm Total Height: 1900-2000-2100 mm Support Length: 900 mm Spacing Between Shelves: 60-100-115-120-140-150 mm Total Mass: 500-600-750-1000 kg (50kg per shelf) The Dynawrap Rack Series is a testament to innovative design and engineering, delivering solutions that significantly enhance efficiency, reduce costs, and streamline operations in workshop environments. It offers a versatile and reliable choice for businesses seeking high-performance drying racks that adapt to their specific needs.

No represented companies found.

- DYNAWRAP

TR

TR